South African Customs has introduced non- intrusive inspection (NII) capability at the Port of Cape Town. The recent completion of an impressive relocatable scanner facility within the port precinct will now afford state of the art inspection services for customs targeted consignments for inspection. This is the third X-Ray scanner installed and operated by the South African Revenue Service (SARS).

In March 2008, a mobile scanner was implemented at Durban Container Terminal. More recently, a relocatable X-Ray Scanner was implemented adjacent to the container terminal in Durban to allow for improved capacity and efficiency.

The new facility in Cape Town not only extends customs risk and enforcement capability in the use of such technology but acts as a deterrent against any possible threat posed by international cargoes entering or leaving the country’s ports of entry.

In addition to the new x-ray inspection hardware, SARS has developed bespoke support to allow scanned images to be reviewed remotely – away from the port area – affording customs increased flexibility, allowing image analysis experts elsewhere in the country to provide almost real-time analysis and support for the inspection team. The approach also meets SARS differentiated inspection case methodology which ensures that case finalization and cargo release does not rest with a single customs official.

Remote screening analysis is a practice that has already been pioneered in Europe with great effectiveness in recent years.

The benefit of non-intrusive inspection (NII) allows customs to ‘see whats inside’ the container, vehicle or tanker without having to break the seal. All of this can be done in a few minutes. It forms part of Customs overall approach to minimise the time taken to conduct a customs intervention and latent cost, damage and theft which plague conventional physical inspection of cargoes.

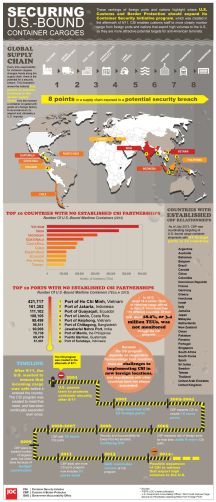

The new inspection site also enables SARS to increase its participation and effectiveness in the US Container Security Initiative (CSI) which was launched in Durban, December 2003. Under the CSI Agreement, SARS officials together with US Customs & Border Protection Agency (USCBP) officials – co-located at the Port of Durban – analyze and mitigate risks relating to any containerised cargo destined to ports in the United States.

Credit to Indresan Reddy (Customs Business Systems) for the photographs.

Related documents

- CSI Ports (cbp.gov)

- CSI Brochure (cbp.gov)

- CSI Containerized Cargo Sealing Policy (cbp.gov)

Hong Kong Customs mounted a special operation at Lok Ma Chau Control Point to combat organised cigarette smuggling activities. About 1.1 million sticks of suspected illicit cigarettes with a market value of about $3.1 million and duty potential of about $2.2 million were seized. A 52-year-old male driver was arrested and the vehicle used for conveying the suspected illicit cigarettes was detained.

Hong Kong Customs mounted a special operation at Lok Ma Chau Control Point to combat organised cigarette smuggling activities. About 1.1 million sticks of suspected illicit cigarettes with a market value of about $3.1 million and duty potential of about $2.2 million were seized. A 52-year-old male driver was arrested and the vehicle used for conveying the suspected illicit cigarettes was detained. An intricate web of smugglers, which reportedly involves manufacturers and middlemen, has been illegally carting cigarettes worth millions of dollars out of the country over the years, prejudicing the treasury of vital revenue.

An intricate web of smugglers, which reportedly involves manufacturers and middlemen, has been illegally carting cigarettes worth millions of dollars out of the country over the years, prejudicing the treasury of vital revenue. The International Maritime Bureau has been alerted to a fraud involving a shipping container’s weight and size that is atypical of what one might out of a container weight fraud case; the tare weight, or unladen weight of the container itself was unrealistically falsified and much higher than the actual, correct weight of the container.

The International Maritime Bureau has been alerted to a fraud involving a shipping container’s weight and size that is atypical of what one might out of a container weight fraud case; the tare weight, or unladen weight of the container itself was unrealistically falsified and much higher than the actual, correct weight of the container.![Cargo Screening [www.aircargonews.net]](https://mpoverello.com/wp-content/uploads/2014/08/cargo-screening-www-aircargonews-net.jpg?w=300&h=146)

You must be logged in to post a comment.