Here’s an interesting view on containers, presented by Alex Colas from Birkbeck University, USA. Colas highlights that containers have been fundamental drivers of global processes and have had an unprecedented effect on logistics and labour organisations. Moreover Colas demonstrates that containers as well as being transformative objects in themselves, have also transformed the way in which circulatory barriers have been overcome through seamless transitions from water to land. Containers are a worthy protagonist of material analysis in international systems and there is much room in academic discourse for the full story of the container to unfold. Herewith the link to the article Thinking Inside the Box, available on the blog – Geopolitics & Security.

Category / Container Security

Is Google moving into box tracking?

![]() The US Patent and Trademark Office has granted Internet search giant Google a patent on a system for securing, monitoring and tracking containers. According to United States Patent 8284045, it describes a two-way communication system, supported by an electronic bolt seal, a network gateway, a web-based platform, and a mobile device, that allows containers to be networked for the transfer of data. Shipping containers are networked for transferring data between the shipping containers. The shipping containers include sensors for detecting conditions associated with the shipping containers. The conditions sensed by any shipping container whether transported by rail or ship is transmitted from an ad hoc network, via a gateway configured for satellite or cellular communications for example, to a container-tracking application server or equivalent computer system. The computer system is remotely located to the shipping container for central compilation, analysis, and/or display of data regarding the shipping containers.

The US Patent and Trademark Office has granted Internet search giant Google a patent on a system for securing, monitoring and tracking containers. According to United States Patent 8284045, it describes a two-way communication system, supported by an electronic bolt seal, a network gateway, a web-based platform, and a mobile device, that allows containers to be networked for the transfer of data. Shipping containers are networked for transferring data between the shipping containers. The shipping containers include sensors for detecting conditions associated with the shipping containers. The conditions sensed by any shipping container whether transported by rail or ship is transmitted from an ad hoc network, via a gateway configured for satellite or cellular communications for example, to a container-tracking application server or equivalent computer system. The computer system is remotely located to the shipping container for central compilation, analysis, and/or display of data regarding the shipping containers.

The system describes an environmental sensor that can travel with a product within a carrier’s logistics network. The environmental sensor being configured to sense an environmental condition capable of affecting the product to generate product environment data. The system includes a scanner configured to read product environment data from the environmental sensor. The system also includes a hub control unit configured to communicate with the scanner and receive the product environment data from the scanner and determines whether the product environment data transcends a limit of exposure of the product to an environmental condition. The hub control unit is also configured to generate a transporting instruction to redirect transport of the product to an alternate destination different from its original destination if the hub control unit determines that the product environment data indicates the environmental condition of the product has transcended the limit of exposure. What a mouthful! I dare say that there are people out there that can decipher the patent content and relate to its various diagrams. If you are interested in this topic, please visit the following link – http://www.archpatent.com/patents/8284045. Also visit the Patent Buddy for similar information. Hopefully as the business case for this patent unfolds things may become a bit more clearer – and perhaps a little sinister too for some!

Related articles

Outcome of Revision of ISO Seal Standard closes 23 December

The International Seal Manufacturers Association has informed that ISO is conducting an up-or-down ballot on an important revision to ISO17712. The revision addresses the difficulties with implementing Clause 6 of ISO 17712:2000.

The essence of the revision is –

- The revision removes the requirement for independent lab testing for tamper evidence.

- The revision adds a mandatory requirement for development and approval of tamper evident improvement programs. The programs must pass independent audits in accordance with ISO 9001 and ISO 17712 Normative Annex A, “Seal manufacturers’ security-related practices.” Audits would review the results of any internal testing related to tamper-evident features.

The mandatory requirement applies to high security “H” seals, which are most relevant to marine containers. Indicative “I” and Security “S” seal participation is optional in this proposed amendment.

The ballot is for ISO FDIS 17712; a FDIS is a Final Draft International Standard. Ballots are cast by national standards bodies such as the American National Standards Institute (ANSI) and the British Standards Institute (BSI), “one nation, one vote”. Each national body determines its vote by its own procedures, usually based on a poll of its members. Since the ballot closes 23 December, we expect the results to be known early in January.

Related articles

- Where Does the Chain of Custody Begin? (mpoverello.com)

- Adoption of container tracking will accelerate in the coming years (mpoverello.com)

- RFID – its application at the Customs border (mpoverello.com)

- Importance of Seal Integrity for Customs (mpoverello.com)

- Customs seal reporting requirements (Andre Landman – SARS)

CBP Maritime Operations resume after hurricane ‘Sandy’

A U.S. Customs & Border Protection Mobile Radiation Portal Monitor (MRPM) drives down a row of containers checking them for radiation.The truck will drive down an entire row of containers, scan one side of them and then it will drive down and scan the other side of them.

U.S. Customs and Border Protection’s maritime mission is now back on-line with today’s processing of cargo vessels and containers. “In the aftermath of Hurricane Sandy the people of New York and New Jersey have faced great adversity, the men and women of CBP have been with them each step of the way,” said Robert E. Perez, CBP’s Lead Field Coordinator for CBP in FEMA Region II. “Today’s processing of cargo ships into the Port of New York/Newark marks the next step in CBP restoring its maritime operations here in the greater New York City area and returning to business as usual.”

CBP personnel are on site today processing 161 expected international flights with approximately 31,500 passengers at JFK and 92 expected international flights with approximately 14,500 passengers at Newark International Airport.

To facilitate the flow of goods into the New York area, CBP officers conducted cargo container inspections this morning at the Port of New York/Newark for the first time since Hurricane Sandy battered the New York/New Jersey area. CBP import and entry specialists were back to work as soon as their facility opened last week, processing merchandise to help facilitate the flow of much needed supplies and supporting the United States economy.

CBP worked very closely with the U. S. Coast Guard and the NY/NJ Port Authority to lift waterway restrictions and open marine terminals to cargo vessels. Officers were on site and ready to process shipments as soon as cargo was off loaded. CBP deployed officers to JFK and Newark Liberty International Airport from other parts of the country to assist with the processing of international passengers. Source: FEMA

The Case for Screening-as-a-Service

In an interview with The Maritime Executive, Peter Kant, executive vice president for Rapiscan Systems informed that the primary business of a port is serving as a hub for water-borne commerce and all of the logistics that entails, with each port competing for the business of shippers and container operators. Every investment made by a port authority, from a crane to a dredge to a security checkpoint, must be based on how this activity will not only position the port to current customers, but how it will affect the attraction of future customers.

In an interview with The Maritime Executive, Peter Kant, executive vice president for Rapiscan Systems informed that the primary business of a port is serving as a hub for water-borne commerce and all of the logistics that entails, with each port competing for the business of shippers and container operators. Every investment made by a port authority, from a crane to a dredge to a security checkpoint, must be based on how this activity will not only position the port to current customers, but how it will affect the attraction of future customers.

Increasingly, however, these investments are including more and more security needs, from container scanning equipment to operator training to security architectures. Security, and in particular security screening, is not the core business of a ports authority, but compliance with national and international guidelines demands that certain security standards be met, or losing customers will be the last of a port authority’s worries.

But even though security screening is an absolute necessity, many ports are looking to get out of the security game altogether. But will the departure from security make ports less secure…or could it actually enhance cargo scanning operations?

The Heavy Burden of Screening

As mentioned earlier, port authorities are not experts when it comes to security, especially a task as granular as cargo screening. It’s not just about a “mean guard and a magnet” when it comes to screening anymore, and this especially holds true to the world of maritime cargo. First, the right technology must be installed, a solution that can effectively analyze cargo for potential contraband or threats, both conventional and radioactive. Then, a port authority must determine the best location for the screening checkpoint, and oversee the construction of the location, both in terms of port impact and traffic optimization.

Next come the installation and calibration of the scanning technology, as well as the hiring and training of security operators. The authority must also establish a workflow for what happens when a container is flagged – what requires a manual inspection? Who approves such an operation? What remediation must take place after the fact?

The fact of the matter is, cargo scanning isn’t just about putting containers through an X-ray machine. It’s much, much more than that, and consumes enough time that establishing and running a checkpoint can adversely affect port business.

But there is an easier way to run cargo screening operations. Port authorities are experts in maritime commerce, so why shouldn’t they turn to experts in security screening to run cargo scanning operations?

Cargo Scanning-as-a-Service

Rather than trying to become cargo screening experts overnight, port authorities can take advantage of a major trend in the overall security world: security-screening-as-a-service. Essentially, port operators form a partnership with an experienced security screening solutions provider, tasking the provider, not the port, with the onus of establishing and running a cargo scanning checkpoint.

Other than the obvious benefit of freeing the port authority from the security logistics headache, why turn to cargo screening as a service? For one, 100 percent screening in the United States has not gone away…at least not yet. But even if the requirements on cargo entering the USA are loosened, port screening for contraband is not going to decrease – in this economic climate, governments want to ensure that everything that can be taxed is taxed. This is a nightmare scenario for port authorities to deal with, but one with which screening solutions provider are comfortable. With their experience in the field, these providers can find the right equipment and checkpoint set-up to be as thorough and detailed as needed when it comes to cargo scanning, ensuring that not only are potential threats detected, but any contraband can be swiftly dealt with by the appropriate authorities.

Going with an experienced screening partner can also add radiation detection capabilities, a growing problem in the world of maritime commerce. Radioactive materials, either improperly labeled or being shipped as contraband, can shut ports down for days and are impossible to detect via conventional cargo screening technologies. By utilizing screening-as-a-service, however, port authorities can place this additional burden on the solutions provider, which has the experience and the right capabilities to detect radiation alongside conventional contraband and threats.

Training of security operators is another headache that cargo scanning as a service eliminates for the port. The difference between a major international incident and millions of dollars in fines can hinge entirely on the competency of a security screening operator. Do port authorities really want to be responsible for the skills of these professionals, especially when it’s in a field far outside of their comfort zones?

With cargo scanning as a service, training falls into the lap of the solutions provider, a task with which they are well familiar. Because they have built, installed and maintained the security technologies selected, these organizations best understand how to train professionals on the ins-and-outs of analyzing scanned images and detecting potential threats and contraband.

The service also gives ports a major competitive advantage, as a well-designed, specially-staff cargo scanning checkpoint makes the entire security process far easier for customers to deal with. Throughput is often increased, meaning that cargo makes it to its end destination more quickly and with fewer roadblocks, a paramount concern for shippers everywhere. Even a few hours delay can be costly, especially when perishable goods like imported produce are involved.

The Real World

Perhaps most importantly, cargo-scanning-as-a-service is not a pipe dream or some theoretical solution for ports. It’s already in practice and being used by some of the largest customs and port operations in the world.

The Ports Authority of Puerto Rico, for example, utilizes cargo-screening-as-a-service from a customs perspective, ensuring that no contraband is entering the island through its major ports. By enlisting an outside, specialized security solutions provider, the Port has increased throughput without sacrificing the integrity of its customs or security operations.

The Mexican Customs Authority has also turned to a wide-ranging cargo-screening-as-a-service solution for their operations, both land-locked and maritime. The major project has just recently been undertaken, but ultimately the vast majority of Mexican ports will soon be turning to screening-as-a-service when it comes to cargo, freeing the ports to focus on the business, not contraband detection.

Detecting threats and contraband via maritime cargo is not going to get any easier. If anything, smugglers, criminals and terrorist organizations are becoming more and more clever when it comes to getting illicit goods, weapons and hazardous materials across national borders. Port authorities trying to stay one step ahead of these issues are in for a struggle, as other aspects of the port business suffer.

Keep the port operator’s attention where it belongs (on the port) and let specialized experts handle the cargo scanning burden. It’s proven, it works, and it’s the best way forward to maritime prosperity and safety. Source: The Maritime Executive

Related articles

- Nigerian Customs Boss unveils new scanners (mpoverello.com)

Dynamic X-Ray imaging – detecting objects or living creatures

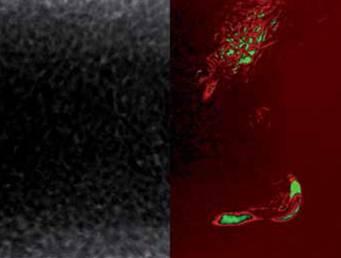

The conventional image (left) and the dynamic image (right) of a pack of rice containing mealworm larvae

X-ray inspection systems are a standard feature in many ports. These X-ray systems have the unique ability to non-destructively image the contents of entire cargo containers in just a few seconds. It is a difficult task, however, to identify what is in the container based on the obtained X-ray images. The superposition of two images with different contrasts – like in dual-energy X-ray imaging – can enhance the effectiveness of the detection. A novel X-ray imaging technology now introduces an entirely new type of contrast based on movement. This technology can be combined with existing single-energy and dual-energy X-ray imaging methods, opening new possibilities in port security applications.

One important application of the dynamic imaging technology could be finding stowaway pests in the cargo. Stowaway pests travel hidden within transported goods and may damage the cargo while being shipped. In addition to this, potentially invasive species often travel as stowaway pests and arrive to new territories unnoticed. Although better part of these exotics are harmless, approximately 20 to 30 percent of the introduced species are pests and cause major environmental and economic problems. Read the full article here! Source: Porttechnology.com

Related articles

- Optimising a layered port security system (mpoverello.com)

Cargo Crime – Security and Theft Prevention

A must read for Supply Chain practitioners. Cargo crime—including theft, fraud, and the passage of contraband through commercial shipping lanes—poses an enormous threat to security and the economy.

A must read for Supply Chain practitioners. Cargo crime—including theft, fraud, and the passage of contraband through commercial shipping lanes—poses an enormous threat to security and the economy.

By understanding the current methods and operations of those who attack the supply chain, industry professionals can design effective security plans and law enforcement can properly investigate these crimes.

Cargo Crime: Security and Theft Prevention is drawn from the author’s (John J. Coughlin) personal experiences as a law enforcement detective and supervisor and as a regional security manager for a large multi-modal transportation and logistics company.

The book reviews emerging trends, identifies criminal tactics, discusses law enforcement response to cargo theft, and presents best practices to help businesses avoid victimization by cargo thieves. Topics include:

- The various modes of freight transportation and the differences in cargo crime activity in each mode.

- Methods of operation used by organized crime syndicates and narcotic smugglers.

- The effective use of public and private information-sharing partnerships to thwart criminal activities.

- Known profiles consistent in over 90 percent of contraband shipments.

The book features the following key aspects:

- Identifies current methods of operation being used by organized and opportunistic criminals who target the supply chain.

- Discusses current law enforcement efforts and response to cargo theft.

- Examines the various modes of freight transportation and the differences in cargo crime activity in each mode.

- Outlines best practices for industry practitioners to prevent being victimized by cargo thieves.

- Addresses industry and law enforcement public/private partnerships for sharing information, educating law enforcement, and circumventing the cargo theft issue.

Cargo crime is a critical concern of freight transportation operators, manufacturers, shippers, insurers, law enforcement, and consumers. This book arms professionals charged with protecting the supply chain with essential information that can help them investigate and uncover criminal activity and develop a first class cargo security program. Available for purchase from http://www.crcpress.com.

Nigerian Customs Boss unveils new scanners

The Comptroller General, Nigerian Customs Service (NCS), Alhaji Inde Dikko Abdullahi, said that ports users would henceforth complete their business transactions within 24 hours. Speaking at the formal unveiling of the gantry scanner procured by Societe Generele Surveillance (SGS) Nigeria at Onne, Eleme Local Government Area, Rivers State, he said the new scanning facilities would boost the 48-hour target for clearance of goods at the ports, noting that it would complement government’s efforts toward reducing the cost of doing business at the ports.

The Comptroller General, Nigerian Customs Service (NCS), Alhaji Inde Dikko Abdullahi, said that ports users would henceforth complete their business transactions within 24 hours. Speaking at the formal unveiling of the gantry scanner procured by Societe Generele Surveillance (SGS) Nigeria at Onne, Eleme Local Government Area, Rivers State, he said the new scanning facilities would boost the 48-hour target for clearance of goods at the ports, noting that it would complement government’s efforts toward reducing the cost of doing business at the ports.

Special training for a select team of 80 NCS officers has been concluded. The team is expected to take over services and operations in the Destination Inspection scheme as from January 1, 2013. The training covered all aspects of the DI activities being handled by SGS for NCS with emphasis on actual risk analysis and processing of the importer’s final document resulting in classification and valuation opinion.

Managing Director of SGS Scanning Nigeria Limited, Mr. Nigel Balchin, in his address at the occasion, said the mobile cargo scanners were capable of scanning about 34 trucks per hour as against 16 per hour by the fixed cargo scanners. Each had double tunnel that enabled it scan two trucks at the same time with equal image quality as the fixed scanner. “At SGS we are committed to quality service delivery. We are very glad to be part of this success story and we look forward to Nigeria Customs Service taking charge of the DI programme. The knowledge you have acquired is for the benefit of Nigeria Customs Service and ultimately that of the Nigerian economy. We wish you the best in your future endeavours”, he said.

The image quality of the relocatable gantry scanners is on par with a fixed scanner. Trucks remain stationary during scanning (the scanner moves on rails) unlike a fixed scanner where the truck is pulled through the scanner on a conveyor that’s more vulnerable to maintenance issues. The scanner is mounted above ground unlike a fixed scanner where one of the detectors is four metres underground. In addition, a relocatable gantry scanner can be re-deployed to an alternative site, in a relatively short time, in case of any expansion or new development.

SGS is one of the service providers contracted by the Federal Government to assist the NCS facilitate trade through risk management and use of non-intrusive inspection (x-ray cargo scanning) of imports routed through the nation’s air and sea ports as well as approved borders. The company is currently providing cargo scanning services in Bahrain, Cameroon, Haiti, Madagascar, Uruguay and has completed provision of scanning services in Gambia, Kosovo and Mexico. Source: Leadership.ng

Related articles

Revisiting the national transit procedure – Part 2

You will recall a recent challenge by trade to SARS’ proposed implementation of mandatory clearance of national transit goods inland from port of initial discharge – refer to Revisiting the national transit procedure – Part 1.

You will recall a recent challenge by trade to SARS’ proposed implementation of mandatory clearance of national transit goods inland from port of initial discharge – refer to Revisiting the national transit procedure – Part 1.

First, some background

Now lets take a step back to look at the situation since the inception of containerisation in South Africa – some 30 years ago. Customs stance has always been that containerised goods manifested for onward delivery to a designated inland container terminal by rail would not require clearance upon discharge at initial port of entry. Containers were allowed to move ‘against the manifest’ (a ‘Through Bill’) to its named place of destination. This arrangement was designed to expedite the movement of containers from the port of discharge onto block trains operated by Transnet Freight Rail, formerly the South African Railways and Harbours (SAR&H) to the inland container terminal at City Deep. Since SAR&H operated both the national railway and the coastal and inland ports, the possibility of diversion was considered of little import to warrant any form of security over the movement of containers by rail. Moreover, container terminals were designed to allow the staging of trains with custom gantry cranes to load inland manifested containers within a ‘secure’ port precinct.

Over the years, rail freight lost market share to the emergence of cross-country road hauliers due to inefficiencies. The opening up of more inland terminals and supporting container unpack facilities, required Customs to review the matter. It was decided that road-hauled containers moved ‘in bond’ by road would lodge a customs clearance (backed with suitable surety) for purposes of national transit. Upon arrival of the bonded freight at destination, a formal home use declaration would be lodged with Customs. Notwithstanding the surety lodged to safeguard revenue, this has the effect of deferring payment of duties and taxes.

Diversification of container brokering, stuffing and multi-modal transport added to the complexity, with many customs administrations failing to maintain both control and understanding of the changing business model. Equally mystifying was the emergence of a new breed of ‘players’ in the shipping game. Initially there were so-called ‘approved container operators’ these being ocean carriers who at the same time leased containers. Then there were so-called non-approved container operators who brokered containers on behalf of the ocean carrier. These are more commonly known as non-vessel operating common carriers or NVOCCs. In the early days of containerisation there were basically two types of container stuffing – full container load (FCL) and less container load (LCL). The NVOCCs began ‘chartering’ space of their containers to other NVOCCs and shippers – this also helped in knocking down freight costs. This practice became known as ‘groupage’ and because such containers were filled to capacity the term FCL Groupage became a phenomenon. It is not uncommon nowadays for a single FCL Groupage container to have multiple co-loaders.

All of the above radically maximised the efficiency and distribution of cost of the cellular container, but at the same time complicated Customs ‘control’ in that it was not able to readily assess the ‘content’ and ownership of the goods conveyed in a multi-level groupage box. It also became a phenomenon for ‘customs brokers/clearing agents’ to enter this niche of the market. Customs traditionally licensed brokers for the tendering of goods declarations only. Nowadays, most brokers are also NVOCCs. The law on the other hand provided for the hand-off of liability for container movements between the ocean carrier, container terminal operator and container depot operator. Nowhere was an NVOCC/Freight Forwarder held liable in any of this. A further phenomenon known as ‘carrier’ or ‘merchant’ haulage likewise added to the complexity and cause for concern over the uncontrolled inland movements of bonded cargoes. No doubt a disconnect in terms of Customs’ liability and the terms and conditions of international conveyance for the goods also helped create much of the confusion. Lets not even go down the INCOTERM route.

Internationally, customs administrations – under the global voice of the WCO – have conceded that the worlds administrations need to keep pace and work ‘smarter’ to address new innovations and dynamics in the international supply chain. One would need to look no further than the text of the Revised Kyoto Convention (RKC) to observe the governing body’s view on harmonisation and simplification. However, lets now consider SARS’ response in this matter.

SARS response to the Chamber of Business

Right of reply was subsequently afforded by FTW Online to SARS.

Concerns over Customs’ determination to have all goods cleared at the coast – expressed by Pat Corbin, past president of the Johannesburg Chamber of Commerce and Industry in last week’s FTW – have been addressed by SA Revenue Service. “One of the main objectives of the Control Bill is the control of the movement of goods across South Africa’s borders to protect our citizens against health and safety risks and to protect the fiscus. “In order to effectively determine risk, SARS has to know the tariff classification, the value and the origin of imported goods. This information is not reflected on a manifest, which is why there is a requirement that all goods must be cleared at the first port of entry into the Republic.“It appears that Mr Corbin is under the impression that the requirement of clearance at the first port of entry has the effect that all goods have to be consigned to that first port of entry or as he puts it “to terminate vessel manifests at the coastal ports in all cases”. This is incorrect. “The statutory requirement to clear goods at the first port of entry and the contract of carriage have nothing to do with one another. Goods may still be consigned to, for example, City Deep or Zambia (being a landlocked country), but they will not be released to move in transit to City Deep or Zambia unless a declaration to clear the goods, containing the relevant information, is submitted and release is granted by Customs for the goods to move. The release of the goods to move will be based on the risk the consignment poses to the country.“It is definitely not the intention to clog up the ports but rather to facilitate the seamless movement of legitimate trade. If the required information is provided and the goods do not pose any risk, they will be released.”

So, where to from here?

The issue at hand concerns the issue of the ‘means’ of customs treatment of goods under national transit. In Part 3 we’ll consider a rational outcome. Complex logistics have and always will challenge ‘customs control’ and procedures. Despite the best of intentions for law not to ‘clog up the port’, one needs to consider precisely what controls the movement of physical cargo – a goods declaration or a cargo report? How influential are the guidelines, standards and recommendations of the WCO, or are they mere studies in intellectual theories?

Related articles

- Revisiting the national transit procedure – Part 1 (mpoverello.com)

- Multimodal inland hubs to add to Gauteng’s container capacity (mpoverello.com)

- Freeing up the containers (portstrategy.com)

- Cargo Owners, 3PLs, Carriers and Ports Stress Need for Genuine Interaction to Improve Container Supply Chain Performance (maritime-executive.com)

- 12 acres in SEZ to be denotified (thehindu.com)

Using Sniffer Bees for cargo screening

Port Technology International (PTI) reported last month, a ground-breaking technological development from UK-based Inscentinel could change the future of security at ports. In a move that brings together nature and technology, bulk cargo screening could soon be carried out by an unlikely source – sniffer bees.

Port Technology International (PTI) reported last month, a ground-breaking technological development from UK-based Inscentinel could change the future of security at ports. In a move that brings together nature and technology, bulk cargo screening could soon be carried out by an unlikely source – sniffer bees.

Freight forwarding companies screen 100 percent of all of their parcels. The first line of screening relies on X-rays followed by REST dogs for special items which cannot be screened. REST, stands for Remote Explosives Scent Tracing.

This works by sampling the air from the cargo through a specially designed filter. This filter, which can trap explosives molecules, is then presented to the most accurate explosives detector ever – dogs. This method has proven very effective to exploit the accuracy of dogs while maximizing the throughput volume of screening, which a free-running dog cannot otherwise do.

According to the information found on the website of Diagnose, a subsidiary of ICTS: ‘The technique has screened over 100,000 trucks and pallets and over 1.5 million metric tons of air cargo since live operations began in the UK and France. The RASCargO™ technique was specially developed to serve the mass screening cargo market that requires a solution for screening high volumes of dense cargo, with actually, no cargo size limitation, a solution that combines high detection rate with cost effectiveness.’ Read the full report as published in PTI here!

Inscentinel’s latest video, below, shows how the company has devised an ingenious way of using the insect in the cargo screening process.

Related articles

- The next best thing to sniffer dogs for cargo screening – SNIFFER BEES.. Yes, really..!! (shippingandfreightresource.wordpress.com)

Dumb, dumber’er, or just plain downright stubborn?

A US statutory requirement to scan all incoming containers at foreign ports will take effect at the beginning of July, a date thrown into sharp relief as the House of Representatives homeland security committee approved a revamped bill that retains the clause.

A US statutory requirement to scan all incoming containers at foreign ports will take effect at the beginning of July, a date thrown into sharp relief as the House of Representatives homeland security committee approved a revamped bill that retains the clause.

The draft bill gave the industry minor cause for cheer for unrelated reasons, as it will postpone the requirement for workers to renew their transportation worker identification cards in the absence of Department of Homeland Security regulations on biometric card readers. But the 100% scanning requirement has proved its resilience yet again.

Since 2006 shippers, spearheaded by associations that include the National Retail Federation, have been campaigning to get the requirement eliminated on grounds that it is impractical and costly and could trigger foreign government retaliation against cargoes originating from the US. US homeland security secretary Janet Napolitano has pointed out the impracticality of the law and proposed a two-year postponement.

These calls went unheeded in the house, as the homeland security committee on Wednesday approved the Securing Maritime Activities through Risk-based Targeting for Port Security Act, known as the Smart Port Security Act. The Smart Port Security Act reauthorises the Security and Accountability for Every Port Act, known as the Safe Port Act, which became law in 2007.

The Safe Port Act implements the 9/11 Commission’s recommendations, including the contentious provision that all US-bound containers will be scanned at origin from July 2012. A fig leaf in the Safe Port Act allows the homeland security secretary to grant waivers to individual ports, under conditions that are somewhat vague. Last year, a Safe port reauthorisation draft in the Senate proposed a broad waiver of the 100% scanning requirement.

With the clock now ticking to July 1, shippers were particularly anxious to get the house bill to remove the 100% scanning clause permanently.

The homeland security committee passed a version that allows DHS to recognise other countries’ trusted shipper programmes and allows the US Coast Guard to recognise other governments’ port security threat assessments, but stops short of jettisoning the 100% scanning clause.

Republican congresswoman Candice Miller, chair of the subcommittee on border and maritime security, hailed the new bill, saying: “Securing our waterways is an essential component of a layered approach to security.

“This bill enhances risk-based security measures overseas before the threat reaches our shores, emphasising a stronger collaborative environment between customs and border protection and the US Coast Guard in sharing port security duties and leveraging the maritime security work of our trusted allies.”

Comment: Huh!, to whom does this refer? Such a statement flies in the face of its own C-TPAT program and bilateral overtures with foreign ports (supposedly based on risk). Perhaps its time for the ‘trusted allies’ to deport CSI teams who have not necessarily endeared themselves to their respective host nations.

Source: Lloydslist.com

Related articles

- Shippers Fail to Scrap 100 Percent Container Scanning Deadline (joc.com)

- US threatens Nigeria over ports’ insecurity (vanguardngr.com)

Hong Kong Customs Moves Forward With E-Lock Plans

The Hong Kong Customs and Excise Department (C&ED) reports that RFID-based container locks can effectively improve the security, convenience and visibility of the customs process for cargo entering the airport. In November 2011, C&ED began testing three types of electronic locks (e-locks) in order to speed up the process of performing customs checks on containers filled with cargo. The solution, known as the Intermodal Transhipment Facilitation Scheme (ITFS), was implemented as a way to streamline the clearance of cargo passing through customs at Hong Kong International Airport for cargo destined for areas both domestic and outside of Hong Kong. The installation and consulting services were provided by the Hong Kong R&D Center for Logistics and Supply Chain Management Enabling Technologies (LSCM), according to Frank Tong, LSCM’s director of research and technology development.

An electronic lock with an active RFID tag is being used to secure freight passing through

customs and Hong Kong International Airport, ensuring that the cargo remains tamper-free,

while also expediting the clearance process.

The Hong Kong C&ED estimates that the system reduces the amount of time required for clearing each container through customs, from two to three hours down to five minutes, since customs officials can now be assured that the containers have not been opened between their inspection at the border control point and their arrival at the airport. What’s more, the agency can now collect a digital record of where each container has been, along with when it was inspected.

Cargo is loaded into freight containers or directly onto trucks—such as those operated by United Parcel Service (UPS)—in Mainland China, and is then transported to a customs control point located at the border with Hong Kong, where C&ED officials inspect the cargo and clear it for entry into Hong Kong. Following that clearance, the shipment continues on to Hong Kong International Airport’s cargo terminal, where the goods are unloaded from the container or vehicle, and are placed into an air cargo container. Once this has occurred, the cargo is moved through another customs control point at the airport, where C&ED again inspects and approves or rejects its passage.

Cargo is loaded into freight containers or directly onto trucks—such as those operated by United Parcel Service (UPS)—in Mainland China, and is then transported to a customs control point located at the border with Hong Kong, where C&ED officials inspect the cargo and clear it for entry into Hong Kong. Following that clearance, the shipment continues on to Hong Kong International Airport’s cargo terminal, where the goods are unloaded from the container or vehicle, and are placed into an air cargo container. Once this has occurred, the cargo is moved through another customs control point at the airport, where C&ED again inspects and approves or rejects its passage.

To speed up this process, the R&D Center implemented the use of an e-lock for the customs agency, consisting of a physical lock activated by a built-in active RFID tag, designed to receive a transmission from an RFID reader that allows the lock to be opened or closed. Three types of e-locks are currently being used, provided by three different vendors: Long Sun Logistics Development Ltd, CIMC Intelligent Technology Co. and CelluWare Research Laboratory. Each of the three products employs a different frequency—433 MHz, 315 MHz and 2.4 GHz—but all comply with the ISO 17712 standard for mechanical seals designed for freight containers.

LSCM has installed fixed RFID readers (provided by the three e-lock vendors) at two border control points—Lok Ma Chau and Shenzhen Bay—as well as at Hong Kong International Airport. When a shipment first arrives at either border control point, C&ED’s staff attaches an e-lock, reads the ID number encoded on its built-in RFID tag via a handheld reader, and links that ID with the vehicle registration number of the truck transporting the container. The transporting company must pre-register each vehicle with the Hong Kong C&ED prior to its arrival; the truck’s ID number is listed in the agency’s database, and the customs official can confirm that the vehicle is, in fact, the one expected.

That data, along with the specific cargo being transported, is then stored on the Hong Kong C&ED’s integrated tracking software platform, developed by LSCM, which collects and processes the data and then displays it for customs officials when necessary. The system stores the e-lock ID number linked to the vehicle ID, and transmits instructions to the e-lock, along with a password, thereby causing it to lock. The device also requires a physical key, which remains in the driver’s possession. In this way, two actions must be completed before the container or vehicle can be unlocked: The e-lock must be electronically unlocked via a password from a customs official, and the driver must use a key to physically open the padlock.

The shipment is then transported approximately 42 kilometers (26 miles) to the airport. The e-lock comes with a built-in GPS device that tracks the vehicle’s location as it moves. In that way, the e-lock stores a record of where the vehicle has been. When the lock is later read at the airport, the back-end software compares the actual GPS data against the container’s expected route. The system can issue alerts in circumstances in which an e-lock is found to have lost a GPS signal, or, based on GPS data, the truck appears to have deviated from the intended route.

At Hong Kong International Airport, a C&ED official either selects the container for inspection, or simply instructs the system to issue an unlocking command with the matching password; the container is then brought to a site where the cargo is removed and then loaded onto an aircraft, says Steve Wai-chiu Chan, a C&ED special duties officer. If the container is selected for inspection, the e-lock remains locked. In this scenario, a truck driver would be instructed to await a C&ED officer, and would be unable to unlock the container without providing the proper password. The C&ED officer, upon arrival, would then use a handheld device to read the e-lock, instructing it to unlock by providing the necessary password.

LSCM installed a total of 38 readers at the two land border control points, five logistic hubs at the airport and a marine control point known as the Kwai Chung Customhouse, for items arriving by sea (at the Marine Cargo Terminal located at the airport). Altogether, by February of this year, 109 containers had been equipped with the e-lock device. An average of 100,000 consignments pass through the border daily, and the ITFS e-lock system is utilized for about 17 percent of that cargo.

The solution has enabled a faster customs clearance process, as well as providing a digital record of what was unlocked, and thus inspected, and when this occurred. The system also improves security, since only officers who know the proper password can access the container. Ultimately, Chan says, “it enhances the Hong Kong logistic industry’s competency and reinforces Hong Kong’s position as a world-class logistics hub.” Source: RFID Journal and a word of thanks to Andy Brown (Tenacent) for bringing the article to my attention.

Royal Malaysian Customs implements Smartag Solution

Smartag Solutions, a homegrown total radio frequency identification (RFID) solutions provider, will handle 1.3 million containers at all Royal Malaysian Customs (JDKM) checkpoints in Malaysia starting June.The company has entered into a two-year agreement with the government to implement and operate the Container Security and Trade Facilitation System using its RFID solutions at the JDKM checkpoints.

Smartag Solutions, a homegrown total radio frequency identification (RFID) solutions provider, will handle 1.3 million containers at all Royal Malaysian Customs (JDKM) checkpoints in Malaysia starting June.The company has entered into a two-year agreement with the government to implement and operate the Container Security and Trade Facilitation System using its RFID solutions at the JDKM checkpoints.

This is the first electronic and electrical Entry Point Project, under the 12 National Key Economic Areas to monitor containers and facilitate clearance within domestic ports and selected high volume routes. The enhancement of container security using the RFID track and trace system reduces the risk of terrorism, dangerous chemicals and contraband from reaching borders while increasing the efficiency of container movement through Customs checkpoints.

The system allows users to use the RFID seal to secure their containers when entering, leaving and moving within the country. Smartag Solutions is expected to handle 50 per cent of the total transactions at the Customs approved by JDKM, or 500,000 containers. Source: BTimes.com

Related articles

- Ethiopia Customs Authority – RFID programme under review (mpoverello.com)

- Advancing the argument for sealing cargo and tracking conveyances (mpoverello.com)

- Taiwan Customs expands e-seal initiative (mpoverello.com)

- RFID – its application at the Customs border (mpoverello.com)

- Importance of Seal Integrity for Customs (mpoverello.com)

Ethiopia Customs Authority – RFID programme under review

Officials at the Ethiopian Revenues & Customs Authority (ERCA) have made a turnaround on their earlier plan to compel IT companies to raise 20 million Br in capital if they are to be registered to supply devises for electronic cargo tracking. Troubled by an increasing practice of pilfering goods on the Addis Abeba to Djibouti transport corridor, the ERCA hired an US-based company for 2.5 million dollars to establish an electronic monitoring system. HI-G-TEK developed the system using Radio Frequency Identification (RFID), which will help customs officials get real-time information on the activities of trucks to and from Djibouti port. There are around 10,000 trucks with varying carrying capacities, of which half are fuel transporting vehicles. A trucking company has to pay around 20,000 Br, including installation fees, to get the devices in each truck under its fleet.

Officials at the Ethiopian Revenues & Customs Authority (ERCA) have made a turnaround on their earlier plan to compel IT companies to raise 20 million Br in capital if they are to be registered to supply devises for electronic cargo tracking. Troubled by an increasing practice of pilfering goods on the Addis Abeba to Djibouti transport corridor, the ERCA hired an US-based company for 2.5 million dollars to establish an electronic monitoring system. HI-G-TEK developed the system using Radio Frequency Identification (RFID), which will help customs officials get real-time information on the activities of trucks to and from Djibouti port. There are around 10,000 trucks with varying carrying capacities, of which half are fuel transporting vehicles. A trucking company has to pay around 20,000 Br, including installation fees, to get the devices in each truck under its fleet.

The US company has installed the system in the six selected stations along the corridor and trained around 30 officers of the Authority. However, the system is yet to be functional, for every truck on the highway should be fitted with electronic tracking devices to be supplied by IT vendors certified by the Authority. In order to be certified, a company is required to have 20 million Br in capital, produce a performance bond worth two million Birr, and have a five-year contract with major IT suppliers, according to the directive issued by the ERCA to regulate the new system. No vendor has been certified, yet, for many see the requirement to raise such lofty capital as an impediment. So far, GCS Tracking Plc, Global Tracking Plc, Ramsea Industrial Solution Plc, and FC Tracking are the companies that have applied to get into the business. The companies are to supply the seals, locks, and compact readers as well as GPRS modems to identify locations of the cargoes.

Subsequent to complaints from the IT industry, legal experts at the ERCA are busying themselves, studying the experiences of other countries, which they hope will be used for possible amendments. However, these experts are divided over the proposition to reduce by half the current capital requirement, while others argue that a performance bond is enough, according to sources. Surprised to hear about the amendment, Zelalem Dagna, managing director of Global Tracking Plc, sees the change as an appropriate move by the ERCA. However, he still claims that the requirement for a two million Birr performance bond should not be removed but be determined on a project basis.

Officials at the ERCA, which is enforcing the current requirements, however, declined to comment. The Authority is also negotiating with the Ministry of Transport (MoT), which is implementing a fleet management system that will also monitor and indicate the whereabouts of trucks, negotiating with the Authority to interface the two systems. Most of the devices used for both systems are the same, thus can run with a single subscriber identification module (SIM) card, transferring all data for the respective institution, according to an electrical engineer at the ERCA. He is concerned that failure to interface the systems would allow transport companies to jack up prices, which he fears would trickle down to the end user.

By all accounts it seems like the initiative was launched on impulse and a whim without prior consultation with stakeholders. Per usual it’s the consultants who have scored out of this. Source: Addis Fortune

Related articles

- Advancing the argument for sealing cargo and tracking conveyances (mpoverello.com)

Where Does the Chain of Custody Begin?

Here follows an article, published by Dr. James Giermanski, an internationally renowned expert in container and supply chain security, international transportation and trade issues. It deals with a crucial but mostly forgotten/unknown aspect of international supply chains – who packed the cargo?

Here follows an article, published by Dr. James Giermanski, an internationally renowned expert in container and supply chain security, international transportation and trade issues. It deals with a crucial but mostly forgotten/unknown aspect of international supply chains – who packed the cargo?

Tracking, tracing, and custody are all generally accepted concepts involving the control of movement. All these concepts have in their fundamental cognitive structure the idea of path, corridor, multiple parts, flow, and coordination.

However, what is often omitted or overlooked is the fundamental sine qua non core principle of “beginning”. What is the beginning of a chain of custody? This article focuses on this core concept and the role it plays as the beginning of the connective custody and control process. Specifically, it addresses the significance of cargo stuffing, the concept of authorized or trusted agent, the means of connectivity, the legal role of the authorized agent, and the consequences of a connected and visible supply chain.

Cargo stuffing

Establishing and maintaining cargo integrity begins with stuffing the container at origin. A chain of custody – chronological documentation or paper trail – involves “the movement and location of physical evidence from the time it is obtained until the time it is presented in court.” As in a criminal case comparison, a supply chain “chain of custody” needs three types of essential assertions:

-

That the cargo is what it purports to be and in the quantity stated;

-

That the cargo was in the continuous possession or control by the carrier who took charge of the cargo from the time it was loaded in the container at origin until the time it is delivered at final destination; and

-

That there is evidence of the identify of each person or entity who had access to it during its movement, and that the cargo remained in the same condition from the moment it was sealed in the container for transfer to the carrier that controlled possession until the moment it released the cargo into the receipted custody of another.

Trusted partner

It is imperative that the initial point of a connectivity process begins at the beginning! Loading cannot take place without a human agent. The agent could be the company’s forklift driver, the dispatcher, the loading dock supervisor, or even an authorizing manager who has a specific duty to verify the cargo and its quantity. It could even be a third party hired by the shipper, for instance, companies that currently provide inspection services around the world.

Various Customs programs discuss, in one way or the other, the concept that supply chain security begins at “stuffing”: the Secure Export Scheme Program (New Zealand); the Partners in Protection Program (Canada); the Golden List Program (Jordan); the Authorized Economic Operator Program (Japan); the Authorized Economic Operator Program (Korea); the Secure Trade Partnership Plus Program (Singapore); and the Authorized Economic Operator.

Establishing ‘connectivity’

Maintaining connectivity depends on the security program, software and hardware utilized. While no system is 100% effective, and one cannot depend on technology alone, there are ‘off-the-shelf’ container security devices (CSDs) that provide connectivity through a sophisticated, comprehensive chain of custody system that begins with loading the container at origin, monitoring it, and reporting on its integrity at the end of the global supply chain path, i.e. at final destination.

CSDs can include the identity of the trusted agent verifying the cargo at loading and the agent’s counterpart at destination. Both parties are electronically connected by a unique identifier to the smart container system along with bill of lading or booking information, or data needed by Customs authorities. Therefore, when the CSD is activated, the accountable party becomes the initiating element in the smart container security system.

Consequences of chain of custody – standards, laws and litigation

If a smart container is opened at destination by an equally accountable person and cargo is missing, and there were no breaches detected, recorded or reported, the accountable person at origin can face either disciplinary, or worse, criminal action by appropriate authorities.

This ESI becomes a source of evidence, should legal action follow. The concept of custody and control from origin to destination also supports Incoterms 2010, a publication of the International Chamber of Commerce (ICC) which provides the playbook of international rules involving international sales of goods. These new terms now contain security requirements for the shipper, making a chain of custody system essential for compliance. There are also changes coming for shippers, consignees, and vessel carriers with respect to carriage of goods by sea: the new Rotterdam Rules.

According to the UN General Assembly, the Rotterdam Rules are a “…uniform and modern global legal regime governing the rights and obligations of stakeholders in the maritime transport industry under a single contract for door-to-door carriage” (cf. American Shipper). The new door-to-door liability places the vessel carrier directly in a chain of custody. Instead of the vessel carrier filing what the shipper said is in the container, the vessel carrier will be automatically and really responsible for knowing what is in the container.

What are the benefits?

The shipper, the consignee, the carrier, and control and regulatory authorities all benefit from a chain of custody system that begins with the loading of the container at origin. CSDs incorporating the identity of the trusted agent at stuffing would assist law enforcement officials to comply with international security and trade standards, solve transhipment problems, impair illegal access to the cargo conveyance, improve supply chain efficiencies, aid in securing hazardous materials and other dangerous cargo movement, reduce counterfeiting, eliminate the in-bond problem of unauthorized container access, and improve bottom line revenue generation for the firms using them. Source: Supply Chain Digest.

Related articles

- US and EU one step closer to Mutual Recognition agreement (mpoverello.wordpress.com)

- Freight forwarders’ liability is being boosted by expanding supply chains (mpoverello.com)

- Weaknesses in the supply chain: who packed the box?

(David Hesketh)

You must be logged in to post a comment.