Click Picture for full report at porttechnology.org [Port Technology International – Container weighing device]

The International Maritime Organization (IMO) is expected to make the weighing of sea containers mandatory. The purpose is to make the entire container supply chain safer. This regulation is expected to be issued through the International Convention for the Safety of Life at Sea (SOLAS Convention) as a result of a number of accidents involving container losses and container stack collapses. The existing SOLAS regulation already obliges shippers to declare the correct container weights, but this is not always done. The new regulation is likely to require specifically that the container is actually weighed or calculated by reference to the contents, packing and securing materials and the tare weight of the container itself. Importantly, however, the regulation is anticipated to forbid the loading of containers unless the verified gross mass is available to the terminal and the ship’s master.

Practically speaking this means that the shipping lines may require terminals to verify container weights prior to being loaded onto their ships. There will, however, be a cost to it which the shipping lines are likely to pass on to their shippers. But besides added safety, there is another important aspect: optimising ship stowage which should reduce fuel consumption for the shipping lines. A ship is more stable at sea and consumes less fuel when the center of gravity is low and if the cargo is optimally distributed. Therefore, it is in the interest of the shipping lines to know the exact weights. Arguably, there are multiple aspects which determine fuel consumption of a ship, and some may be more important than stowage, but this is nevertheless a factor.

Determining container weights and related costs

First of all, to weigh a container and to use the load information to update the stowage plan, containers need to be weighed preferably at the completion of packing. Clearly, weighing export containers needs to be done sufficiently in advance for the stowage plan to be optimised. If the actual weight is not determined at the completion of packing, the port is in a prime position to provide this service or, indeed, to verify the documented weight. For containers that arrive at the port by road, rail or river an obvious ‘check point’ is during the inward process. Weighing with the quay side crane is too late, since the container position on the ship is determined well before loading.

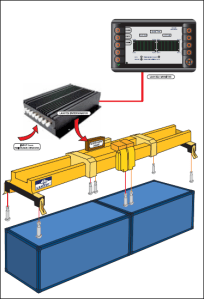

Weights of transshipped containers should be verified at the original port of loading, but there will always be situations where this has not been physically possible. In that event, it can be said with certainty that every container, whether exported or transshipped, will pass through the stacking yard. It is therefore argued that equipping the stacking cranes with weighing systems best caters for all circumstances. Operators in those countries that require imported containers to be weighed may consider weighing with quay side cranes as well.

What does it cost to weigh a container? Let’s base the calculation on the capacity of a quay side crane which can typically load 100,000 twenty-foot equivalent unit (TEU) per year. Let’s also assume there are three rubber-tyred gantry cranes (RTG) or rail-mounted gantry cranes (RMGs) required per quay side crane. Let’s further assume a weighing system costs US$20,000 per stacking crane and it is amortised over three years. The cost per year to weigh 100,000 TEU is therefore US$0,20 per TEU. In addition to the capital expenditure for the weighing equipment, the terminal will incur some integration costs plus ongoing maintenance and administration costs, so let’s double this amount to US$0,40 per TEU. Weighing by the stacking cranes during the handling of the containers is also more economical than weighing with weigh bridges which very often involve manual intervention, when trucks are carrying two 20 foot containers which need to be individually weighed. Weighing in the stacking yard is therefore the fastest, most economical and non-disruptive way to the operation. Some terminals have calculated that they could offer their weighing services for US$1 per TEU and earn a profit with it. Continue reading →

You must be logged in to post a comment.